U.S. Air Force Academy Cadet Saber - Made in the USA

U.S. Air Force Academy Cadet Saber - Made in the USA

Couldn't load pickup availability

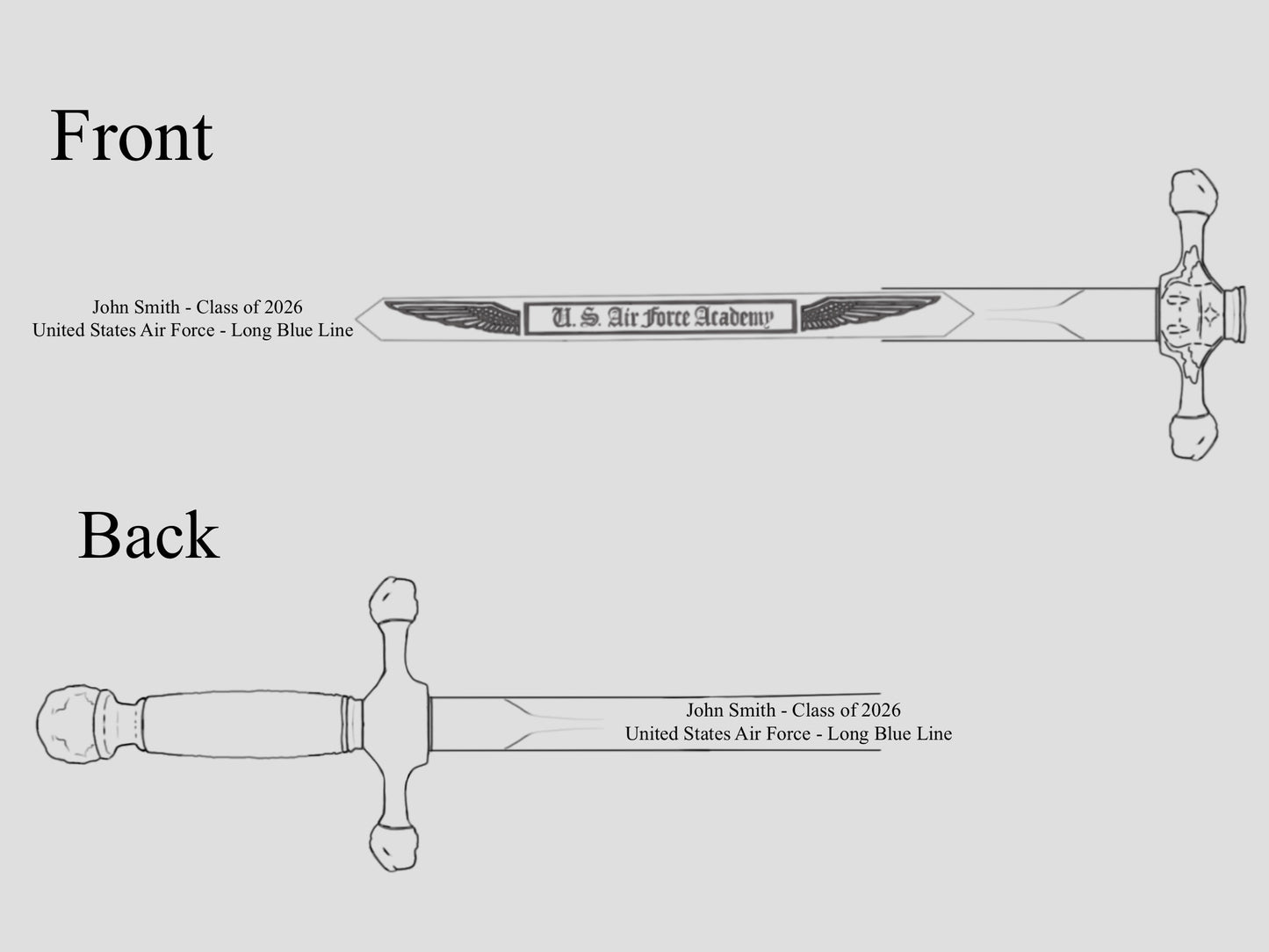

The Official U.S. Air Force Academy Cadet Saber — handcrafted in Colorado Springs by Excalibur and available exclusively through the U.S. Air Force Academy Association. Proudly made in the USA, it stands as a symbol of precision, honor, and Air Force heritage.

Custom Personalization

Personalize your saber with your name and graduation year — a distinguished keepsake that honors your Academy journey and the proud heritage of the Long Blue Line. Personalized orders ship within 4–6 weeks. All personalized sabers are non-refundable.

About the Manufacturer

· Excalibur is a Colorado-based manufacturer working in partnership with Kilroy’s Workshop Inc.

· Kilroy’s Workshop Inc. operates the world’s largest blade smithing school (approved by the American Bladesmith Society), training 4,000+ students each year in forging, heat-treat, welding and precision finishing. Thirteen Kilroy’s Workshop smiths appeared on the History Channel TV show Forged in Fire.

· Kilroy’s Workshop Inc. offers a lifetime guarantee.

Why do the new sabers look and feel different?

· Every saber is entirely handcrafted in-house. As with anything made by hand, small visual variations are normal.

· Critical tolerances (blade-to-guard fit, tang alignment, balance) are held to ±0.005 in. using precision jigs; functional consistency is therefore higher than on prior, partially mass-produced models.

· Blades are made from AEB-L stainless steel — a fine-grained, high-carbon alloy that is heat-treated in house. AEB-L provides excellent rust resistance.

· Blades are polished to a non-reflective “dress satin;” this intentionally appears subtler than the mirror finish on many commercial replicas.

· Bronze guards/pommels are polished, then plated for maximum corrosion resistance.

· Scabbards are TIG-welded, filed and chrome-powder finished as of April 2025.

· Prior scabbards were manufactured with mild steel that would often rust.

· No set screw assembly on the scabbard

· Periodic cleaning with a silicone cloth prevents water spots and maintains the mirror finish.

Tell me about the assembly of the new saber.

· The saber employs a full-length, tapered tang threaded directly into the pommel, eliminating prior-year handle failures caused by a weak point where tangs were welded to short steel rods.

· Guard-to-scabbard alignment is hand blended. Tiny filing marks may remain as each is fit by hand.

What details are different?

· The new saber uses the USAFA crest instead of the Air Force crest.

· The new guard and pommel have more depth of detail than prior sabers. Prior sabers were prone to tarnishing, and buffing compound remained from processing in the crevices.

· A change to both guard and pommel adds more natural shading without relying on tarnishing or buffing compounds.

· The new grip uses a centuries-old traditional wire-wrap technique. Its uniform texture is designed for parade-glove traction. The new wrap leaves no voids or rattle and can be tightened or replaced for decades.

I noticed that saber costs have gone up. Why?

· All materials are sourced domestically.

· Comparable ceremonial swords of similar quality can retail above this price point, often without U.S. origin or lifetime service.

· Your purchase includes free lifetime inspection, polishing and wire-wrap maintenance.

This item is not eligible for discount.

Share